Types of Openings for Kraft Bags

Kraft bags with closed ends are widely used across various industries for packaging powdery and granular products such as cement, flour, sugar, cereals, and chemicals due to their high strength and resistance to moisture and impact. These bags come in various opening types and packaging methods, each chosen based on the specific needs of the product and the packaging process.

1.Pinch Bottom

Kraft bags with pinch bottom openings are among the most common types of closed-end bags. In this type, the bottom opening is tightly sealed using adhesive or heat sealing. After filling the bag, the top opening is sealed in the same manner. This type of packaging is especially suitable for products requiring high protection against moisture and contamination.

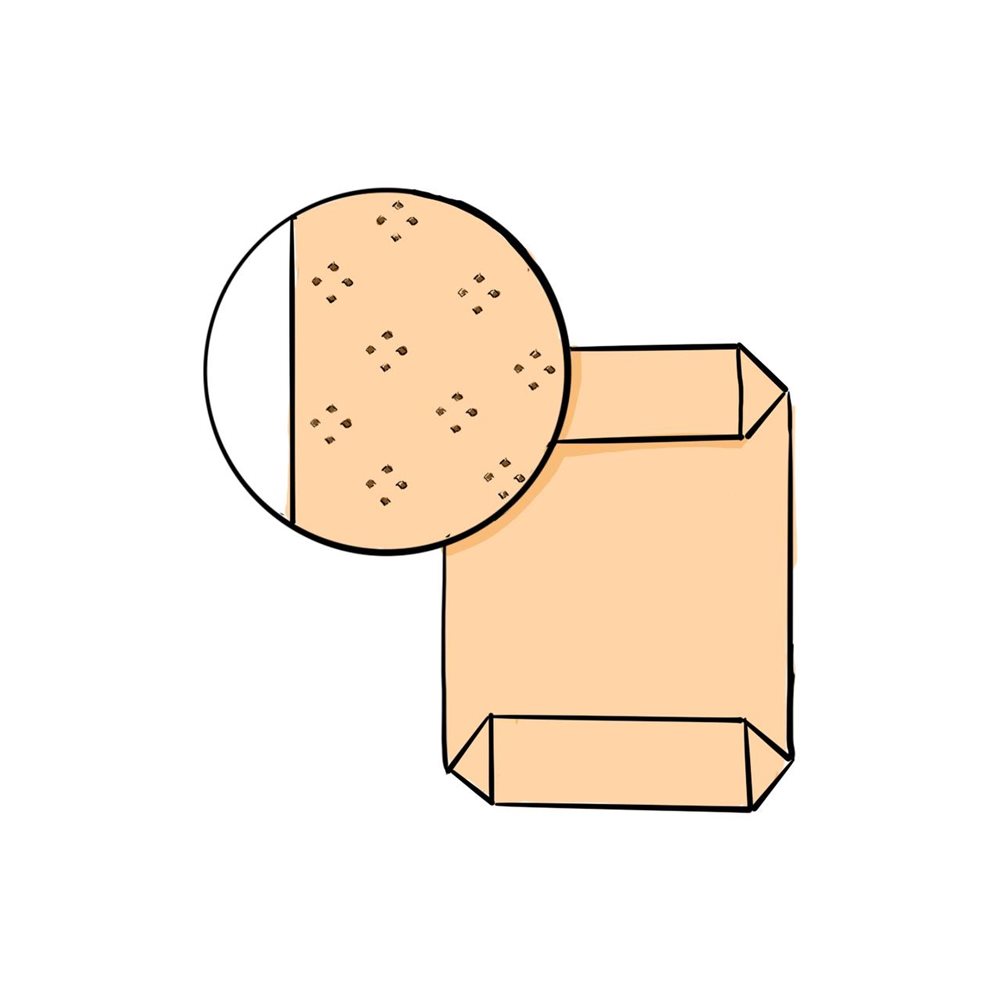

2.Block Bottom

Block bottom or block bottom bags have their bottom part folded into a flat, sturdy block and sewn. This type of packaging allows the bag to sit stably on flat surfaces. After filling, the top opening is also sealed in a similar manner. These bags are suitable for heavy and bulky products like building materials and chemicals due to their strong structure.

3.Pillow Type

Kraft bags with a pillow type opening have a simple and efficient structure. Both ends of these bags are tightly sealed after filling, forming pillow-like closures that prevent air and moisture from entering the package. This type of packaging is used for powdery and granular products like cement, gypsum, and bulk food items.

4.Sewn Closure

In this method, both ends of the bag are sewn using durable industrial threads. This type of closure is typically used for bags that need to be closed quickly and securely. Sewn closures are particularly useful in heavy-duty packaging and where high strength is required, such as for agricultural and industrial products like grains, flour, and minerals.

5.Multi-Wall

Multi-wall Kraft bags feature several layers of Kraft paper and sometimes internal layers made of polyethylene or other protective materials. Due to their multi-layered structure, these bags provide high protection against moisture and air infiltration. Both ends of these bags are usually sealed with stitching or heat sealing. This type of packaging is suitable for moisture-sensitive products and varying environmental conditions.

6.Valve or Spout

Valve or spout openings in Kraft bags are designed for products that require controlled discharge, such as cement or industrial powders. This type of opening allows users to discharge the product precisely without spillage or waste. This feature is particularly useful in the construction industry.

Summary

Kraft bags with closed ends, depending on the type of opening and packaging method, can meet diverse packaging needs across various industries. Choosing the appropriate opening type based on product characteristics and storage conditions can help maintain product quality, ease of use, and reduce transportation costs. These bags are considered one of the best options for packaging industrial and agricultural products due to their strength and high protection.